Ensure access to affordable, reliable, sustainable and modern energy for all

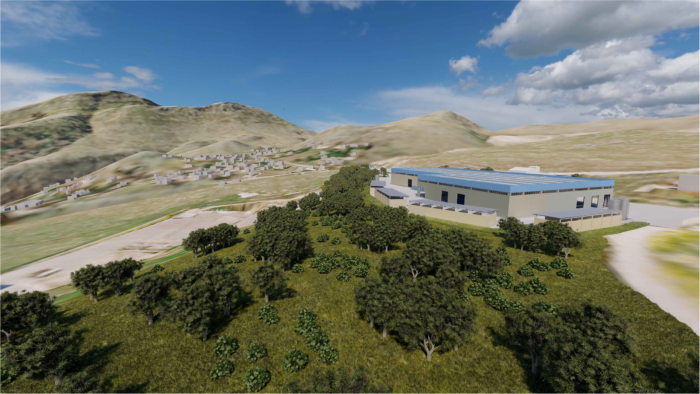

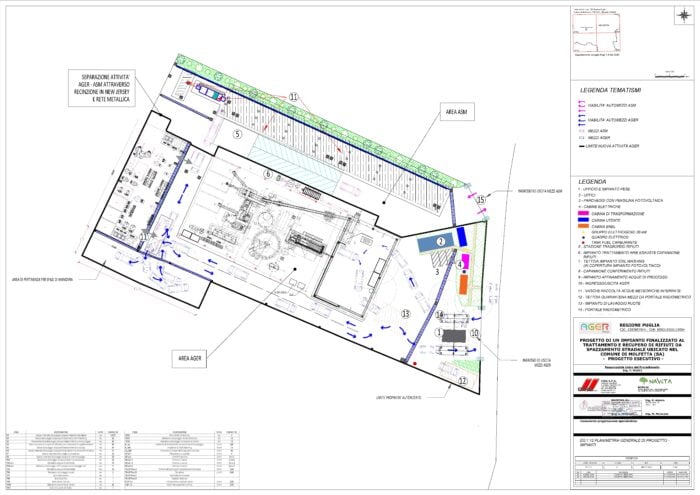

The project foresees the revamping of an existing Mechanical Biological Treatment (MBT) plant, as well as the construction of a new section for the treatment and energy recovery of the Organic Fraction of the Municipal Solid Waste (OFMSW) resulting from source separated collection.

Location

Bellolampo, Palermo (PA)

Data

Type of service:

detailed design,

executive project, construction

supervision, commissioning and

operation monitoring

Design period:

June 2020

Technical data

Total site surface: 40.000 m²

Treatment OFMSW

Capacity: 60.000 t/year

Compost production: 15.200 t/year

Biogas production: 1.040 Sm3/h

Biomethane production: 620 Sm3/h

Treatment OF-MBT

Capacity: 100.000 t/year

Stabilized organic fraction production: 67.300 t/year

Biogas production: 1.230 Sm3/h

Biomethane production: 650 Sm3/h

Added-value products such as biomethane, biofertilizers,

Refuse-Derived Fuel (RDF) will be produced as well as ferrous and non-ferrous metals

recovered.

The project includes:

- Improvement of the organic fraction treatment resulting from the MBT; Improvement of the organic fraction treatment resulting from the MBT;

- Treatment facility for the OFMSW resulting from source separated collection;

- Biofertilizers and quality compost production from the OFMSW (resulting from source separated collection);

- Biomethane production from OFMSW and MSW.

The project integrates the existing facilities with the new industrial structures. The final

layout includes:

- A pre-treatment section for the OFMSW resulting from source separated collection; two anaerobic digestors (AD) to process the organic fraction sourced from the MBT section and the inflow of OFMSW resulting from source separated collection;

- A section for the upgrading of biogas resulting from AD to obtain biomethane;

- A facility to feed biomethane into the natural gas grid;

- A bio stabilization section for the digestate generated from the AD of the OFMSW from undifferentiated collection and sewage sludge (existing);

- A bio stabilization for the digestate generated from the AD of the OFMSW resulting from source separated collection to produce high-quality compost.

As a result, two different waste treatments processes will be integrated:

1. OF-MBT process. This will treat the undersized organic fraction material obtained

though the existing mechanical pre-treatment facility;

2. OFMSW process. This will treat the OFMSW from source separated collection.

The OF-MTB process scope is the treatment of the OF obtained from the existing MBT

facility through a section of dry anaerobic digestion for the production of biogas that will

be sent, together with the one obtained by the OFMSW, to the upgrading facility which

will capture CO2, and therefore, obtaining biomethane. Waste coming from AD will

be subject to accelerated bio-oxidation at the existing biocells. From this process an

inodore outcome with low humidity (less than 50%) is obtained and destined to landfill.

The FORSU process aims to obtain through AD the production of biogas and fertilizer

and/or quality compost. Again, the biogas, which will be upgraded, can be fed directly in

the national grid.