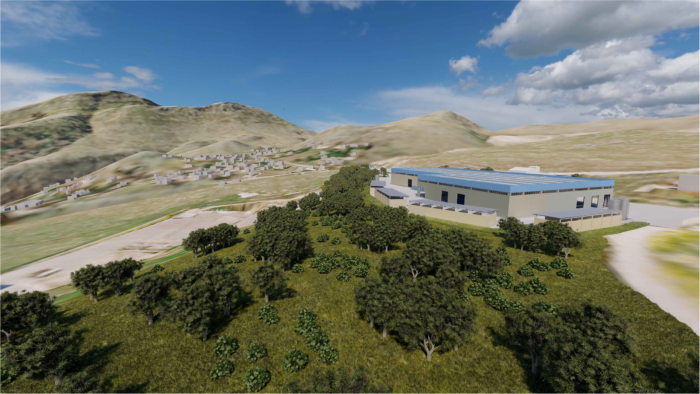

The plant is placed within a very strategic area because it’s near the port of Catania,

well served by the railway tracks. The platform is designed to treat both oily emulsions

and the so-called bilge water that may come from the nearby port area of Catania. The

system can also treat hazardous and non-hazardous liquid waste from the industrial

centers of eastern Sicily (e. g. Priolo Gargallo, Siracusa, Gela, etc.).

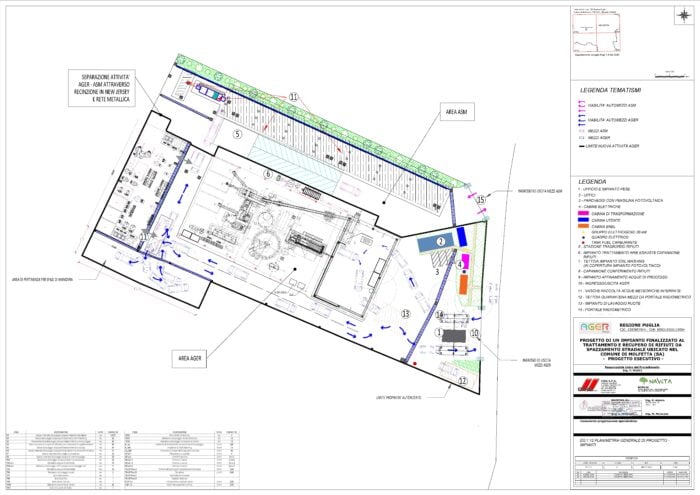

The plant architecture provides the possibility to treat wastewater of different nature

on separate lines. A first slurry line will be devoted to the treatment of sewage with

a high organic load (such as the food industry waste and the spoils of septic tanks),

for which an initial solids separation by grill and a physical – chemical pretreatment

in clariflocculator are provided. A second process line will be dedicated to acidic and

alkaline wastewater, for which a preliminary neutralization and the physical-chemical

treatment in clariflocculator are provided. Finally, A third line slurry will be suited for

the treatment of liquid waste with a high content of oily emulsions, bilge water and so

called “recalcitrant” waste (such as surfactants) and a sedimentation with intercepting

of oil and a preliminary oxidation with Fenton reagent are provided. After the different

stages of pre-treatment, all the sewage lines are equalized and subjected to biological

treatment with activated sludge. Subsequent steps of denitrification and final

sedimentation are then provided. Finally, the tertiary treatments provide a filtration with

sand and activated carbon and a final UV disinfection. The sludge line is constituted by

a mechanical dewatering for the chemical-physical sludge and a thickening followed

by aerobic stabilization and mechanical dehydration for the biological one. All plant

sections are equipped with air suction devices in order to reduce VOC emissions.