Ensure access to affordable, reliable, sustainable and modern energy for all

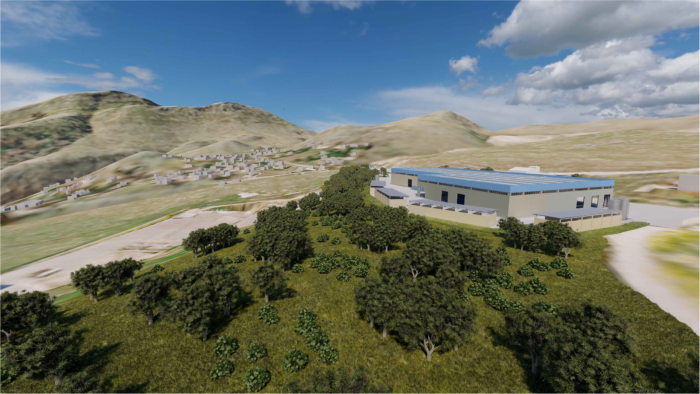

The project aims to improve the composting plant of the Municipality of Salerno, which has a treatment capacity of 30.000 t/year and is operated by Salerno Pulita S.p.A.

Location

Comune di Salerno (SA)

Data

Type of service:

Definitive design

Design Period:

Ottobre 2021

Technical data

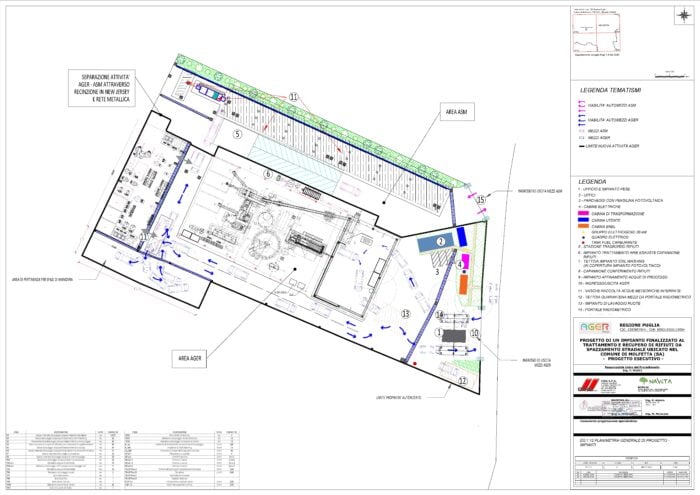

Total site surface:

46.109 m²

Aerobic-anaerobic OFMSW section

Treatment capacity: 30.000 t/year

Produced Compost: 10.140 t/year

Produced Biomethane: 80 Sm3/h

Electric energy: 1.245 MWhel/year

Thermal energy produced: 1.000 MWhte/year

The production process is upgraded to use the BATs and incorporate industry 4.0, interconnectivity and smart automation solutions, such as advanced software, cloud, robotics, and remote monitoring.

Through the abovementioned interventions the existing anaerobic digestion of organic matter will achieve maximum production capacity of biogas, to be fed to the cogeneration process for the production of electricity and thermal energy.

For the revamping of the anaerobic treatment process the following activities are expected:

- Adaptation of the FORSU pre-treatment systems, mainly by replacing the existing press unit with a higher performance machine that integrates advance technological solutions;

- Decommissioning of existing emergency flare, now out-of-service, and installation of new open-flame flare with steady combustion temperature;

- Decommissioning of the existing gasometer system and installation of a new two membrane press static system;

- Inertization with nitrogen, emptying and washing the digesters;

- Revamping of the anaerobic digestion system through replacing the vertical agitators, pumping systems and the polyelectrolyte dissolution system and reconditioning the piping and valves;

- Extraordinary maintenance of the existing biological desulfurization system and revamping of the biogas upgrading system by replacing the cogeneration units;

- Installation of an advanced monitoring system for the composting in-vessel reactors and for the anaerobic digestion process;

- installation of continuous remote automation and monitoring system.