Ensure availability and sustainable management of water and sanitation for all

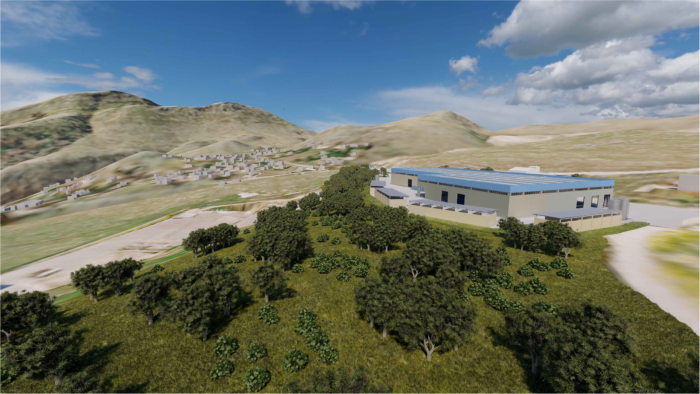

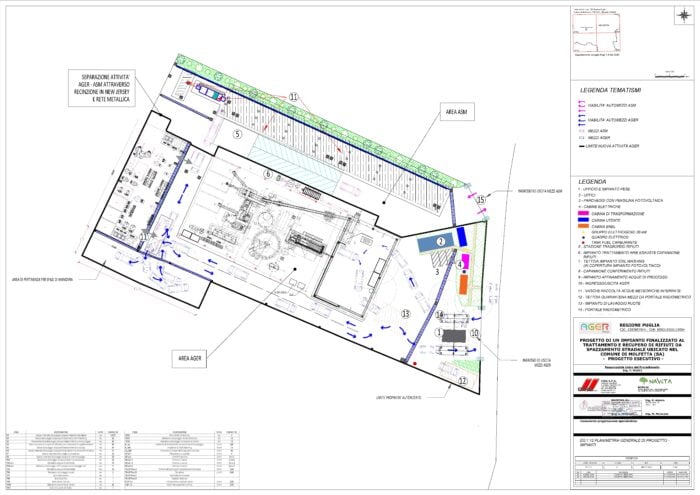

The project involves the construction of a leachate treatment plant serving the entire

landfill site located in c.da Codavolpe (CT), owned by Sicula Trasporti.

Location

C.da Grotte S. Giorgio, Lentini (SR)

Data

Type of service:

Executive

planning and

construction management

Design period:

October 2018 – August 2019

Technical data

Treatment capacity:

500 m³/day

Clarified permeate:

430 m³/day

Amount of concentrate:

70 m³/day

In the authorized treatment plant the leachate coming from the landfill is processed as

follows:

• equalization and preliminary sedimentation of rough materials of coarse solids;

• ultrafiltration;

• 3-stage reverse osmosis;

• reverse osmosis at high pressure (for concentrate).

The leachate is temporarily stored inside the storage units and it is pumped inside an

equalization tank which has buffer function to homogenize the wastewater to be treated

inside this tank, moreover, the sedimentation of the suspended solids of larger dimensions

takes place.

From the tank, the leachate is pumped into the filtration section, for the separation of

the remaining suspended solids; the permeate from this treatment step is pumped into

a feed tank for the subsequent reverse osmosis phases, while the UF concentrate is sent

back into the accumulation tank.

The UF permeate then undergoes reverse osmosis treatment divided into three distinct

phases; in each of them, in any case, the pressure applied to the fluid allows the separation

of dissolved solids in the passage through the membranes.

Finally, from the third reverse osmosis stage, the permeate, which is purified from all

the polluting components of the untreated leachate, is discharged into the underground

storage tank. The treatment plant is completely automatic and also provides the possibility

of remote control and telediagnosis; the plant is equipped with one MMI interface and

SCADA system.