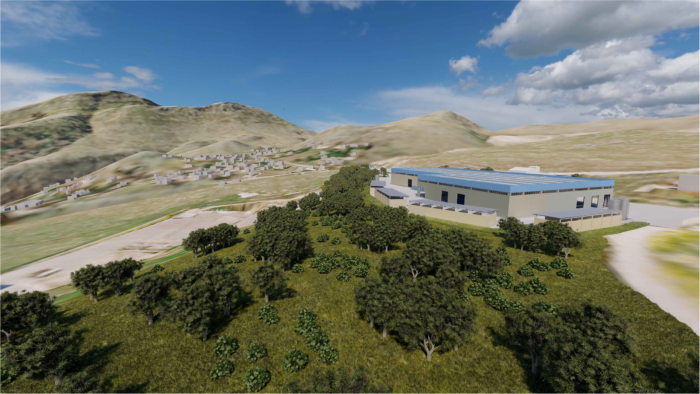

The design is developed in accordance to a public tender for the construction of an

integrated system for the M.S.W. mechanical and biological treatment in the Municipality

of Gela (CIG 553112900C), which was issued by the Commissioner for the Waste Emergency

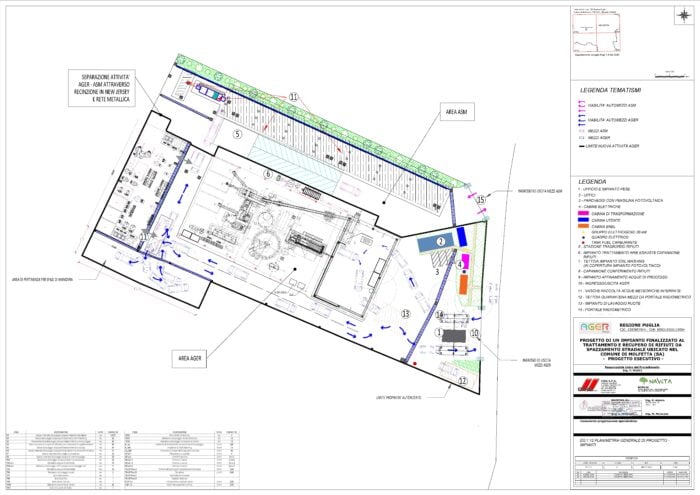

in Sicily (O.P.C.M. 9/7/2010 n. 3887 – D.L. n. 43/2013). The plant lay-out provides two

mechanical treatment lines for the screening of M.S.W. with a capacity of 31.4 t/h overall.

The process-line layout is the following: a wide area for the storage of the incoming

wastes, two screens with 300 mm holes for the separation of non-treatable waste, two

shreddings and double-stage screenings (with holes from 130 to 80 mm). This is aimed to

separate the following materials:

- oversize fraction >130 mm by which nonferrous metals (e.g. aluminium cans) and ferrous

materials will be separated; - oversize fraction 80÷130 mm, by which ferrous materials will be separated;

- underscreen fraction <80 mm, which must be processed with biological treatment.

Oversize materials will be also processed with ballistic and optical separation in order to

separate paper and recyclable plastic materials.

The designed layout is also arranged for future development of a fine-shredding section to

produce RDF, a refining section for the bio-stabilized materials, and a recovery section for

the organic waste from separated collecting of MSW (for producing high-quality compost).

The biological treatment for under screen fractions is aerobic stabilization within closed

air-forced tunnels, in order to obtain stable and dry materials which can be sent to

disposal or recycled. The buildings will be kept in constant depression in order to ensure

the health of workers; the air is recirculated within the aerobic tunnels to facilitate the

process. Lastly, the exhaust air will be treated with two scrubbers and a biofilter, and be

given off into the atmosphere, since pollutant concentrations are reduced to the levels

set forth by law.