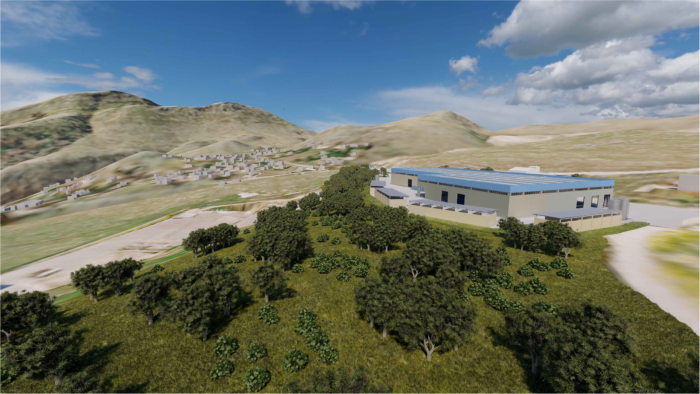

Location

Catania (CT)

Data

Type of service:

Final design, Environmental Impact Assessment, Integrated Environmental Authorization application

Design period:

October 2010 – August 2012

Technical data

Additional surface for new plant:

66.700 m²

The design for improving the existing aerobic biostabilization plant (authorized by the

Italian Decree that regulates integrated environmental authorizations – D.R.S. 1004/2009)

was devised for two different needs:

i) to balance the waste treated with the waste produced by and arriving from the

mechanical treatment plant (which was authorized by D.R.S. No. 248 26/03/2009 to treat

1.000.000 t/y of undifferentiated urban waste);

ii) to provide a new section of the facility to be used for the treatment of organic waste

from the separated collection of MSW, in accordance with the new target (>65% separate

waste sorting) of the “Regional Plan for the management of Municipal Solid Waste of May

2012”.

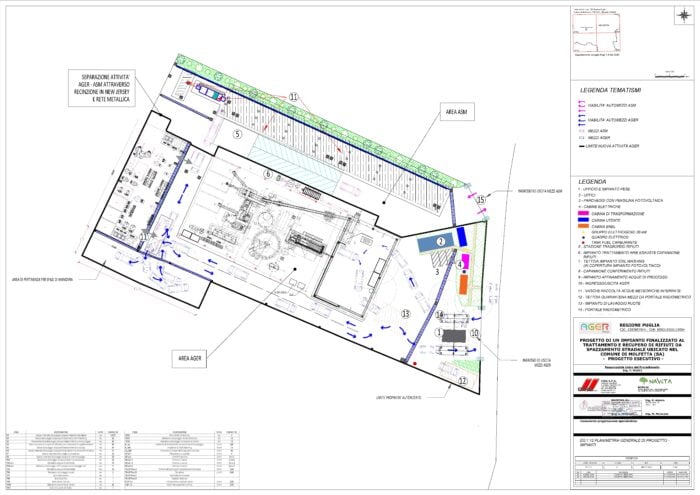

The design regards the construction of:

- A new section for the aerobic treatment of the underscreened materials resulting

from mechanical selection, having a maximum capacity of 150.000 t/y, equal to about

410 t/d (static heaps will be stabilized within 23 closed tunnels, and subject to forced

ventilation). This will increase the current capacity from 315.000 to 465.000 t/y. So the

treatment capacity will be adequate to process the organic waste (about 450.000 t/y)

arriving from the mechanical plant; - A new section for the anaerobic digestion of the organic waste resulting from separate

collection of MSW with production of compost, with a maximum capacity of 75.000

t/y, which are about 205 t/d (process phases: mechanical pretreatments, anaerobic

digestion, within 13 closed tunnels, for the production of biogas which is recovered

within a 1.5 MW cogeneration, stabilization and drying of the digested sludge, within

13 closed tunnels subject to forced ventilation).