Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all

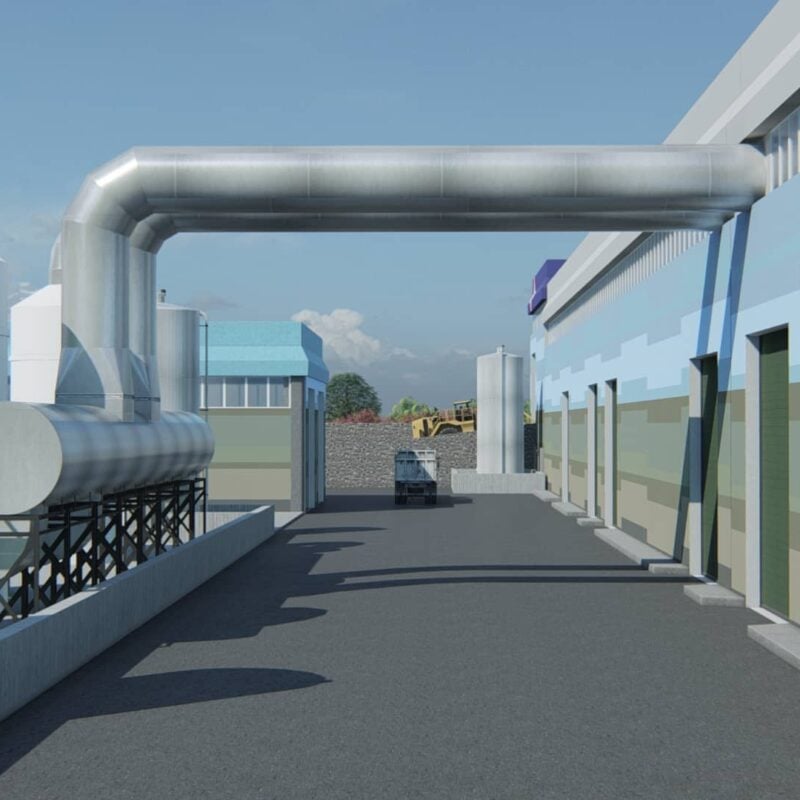

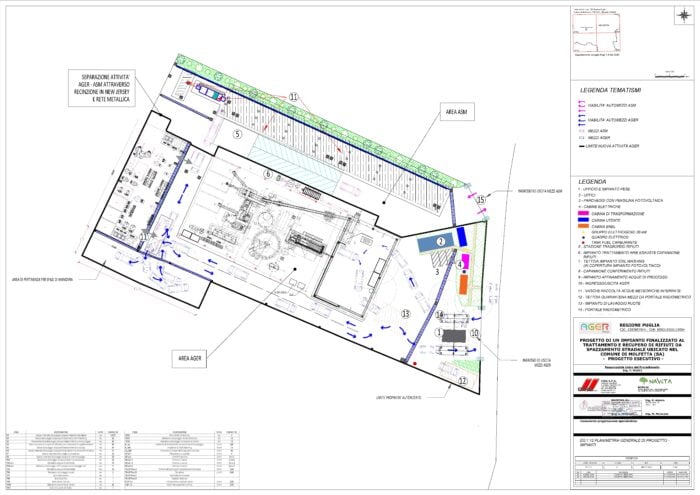

The project concerns the construction of a composting plant for the aerobic biological treatment of the organic fraction of municipal solid waste (OFMSW), collected separately, in order to allow the waste recovery through the production of high quality compost.

This plant falls within the scope of the interventions financed among 2014-2020 by the

Campania Regional Operational Program (POR) based on the European Fund for Regional

Development (ERDF).

The Joint Venture formed by Technital S.p.A., Owac Engineering Company S.r.l. and IA

Consulting S.r.l. has awarded the Lot 2 (prov. CE) of the Framework Agreement and has

signed the contract on 14/03/2019, Rep. N.14550.

The plant has an overall treatment capacity of 30.000 t/year, of which:

• 24.000 t/year dedicated to the treatment of the OFMSW;

• 6.000 t/year dedicated to the treatment/reuse of the wood-cellulosic fraction as

structuring material in the biological process.

The OFMSW is mixed with the shredded structuring green and arranged in aerobic biocells

for the accelerated biostabilization process (18 days). The treated compound is sent to the

primary maturation process in ventilated lanes (45 days) and, following an intermediate

refinement, is sent for the final maturation (27 days) in 6 static heaps periodically turned

over. The obtained compound is ulterior refined to complete the process.

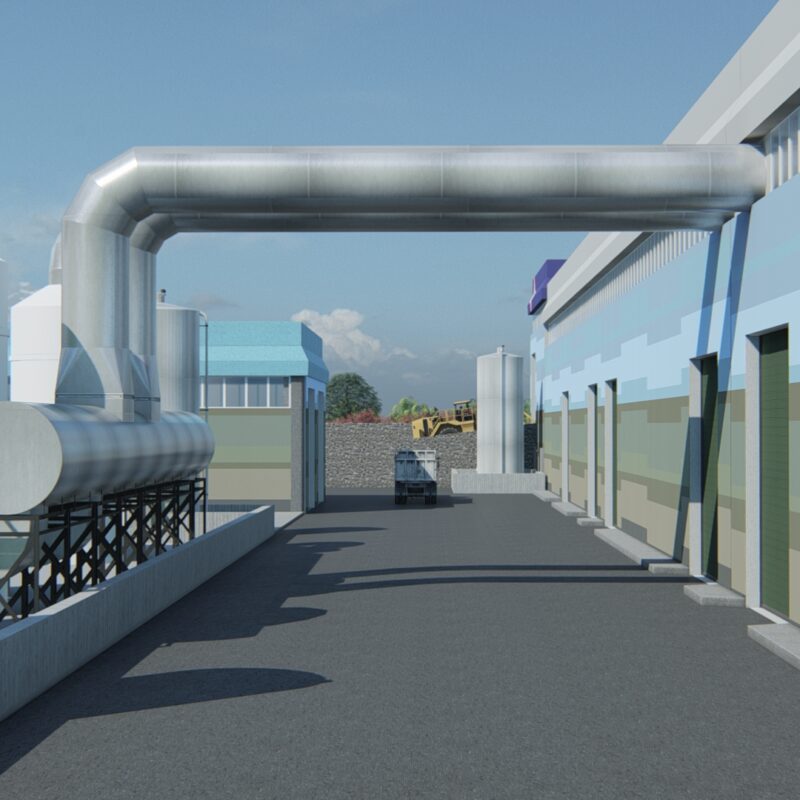

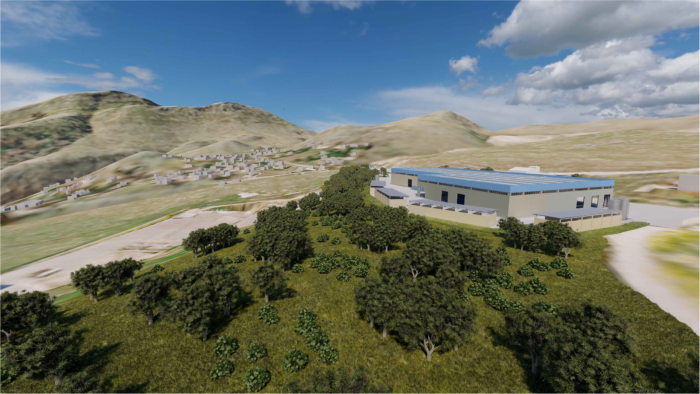

In the Project delivery, in order to limit the environmental and visual impacts of the plant

in long and short terms/space, a full attention has given not only to the process layout

design but even to:

• environmental mitigation measures

• landscape integration

It was decided to use colour as a camouflage tool. Eight colour nuances of the surrounding

landscape are sampled and translated into RAL colours to be applied in the panels of the

buildings. Such panels will be positioned alternating colours and gradation in order to

camouflage the compost plant in the landscape.